There might still be life in those old PV panels...

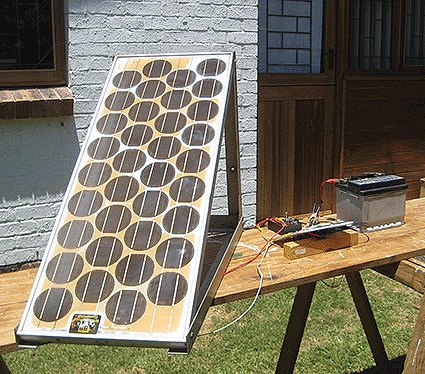

Recently gifted with 2 very aged BP Model BPA 1233 Photovoltaic Generator 36 cell panes began a process to determine whether these were still able to produce any power. Their own weathered frames, the 50mm x 50mm aluminium support frames, spider’s webs and bird droppings indicated that they had been around in open outdoor storage for a long time. How long was the question as the answer would provide some preliminary information as to what to expect?Wire brushed the aluminium frames, removed rusted fixing bolts, window wash solution for the glass, stiff brush cleaned out the junction box.

Specifications:

Make: BP Photovoltaic Generator.

Model: BPA 1233.

Voltage/wattage: 12V DC - 33 watt - 36 silicon cells.

Connection cables: Positive: Brown or Red - Negative: Blue or Black.

BP Solar, a subsidiary of BP, was a manufacturer and installer of photovoltaic solar cells headquartered in Madrid, Spain, with production facilities in India and the People's Republic of China.

Google search: https://en.wikipedia.org/wiki/BP_Solar

The donor estimated that they are at least 20 years old which seems to be confirmed by the degree of discolouration around the cells - see photographs.

The cleaned junction box revealed 4 braided wire strips that were connected to the 2 circuits linking the 18 silicon cells - 36 in total. Measuring each circuit produced 9.75 and 9.5 V DC - a combined total of 18.75 V DC. Silicon cell output is nominally rated at .5 V DC per cell - 36 cells generate 18 V DC - the panel had some life!!

The short braided wire strips were sealed in a layer of silicon which was carefully cut away so as to solder short extension leads needed to connect the 4 braided wire strips to the PC Board diodes.

The 4 short leads were added and a thick layer of marine grade silicon poured all around them and the area where the braided wire entered the PV Panel, to re-establish the previously removed seal.

PC Board reattached - a check from the PC board Positive and Negative terminals gave 18.5 V DC. Was this enough to charge a 12 V lead acid battery?

Time to test:

Time 12:15 The electrically repaired PV panel was orientated directly at right angles to the sun then connected to my monitoring panel with its analog voltmeter, charge controller, secondary digital voltmeter for accuracy and 12 V lead acid battery to check whether the PV Panel will manage to charge.

The volt meters immediately registered a peak voltage of 14.03 V DC which then rapidly scaled down to 13.19 V DC and then cycling immediately back up again to 14.03 V DC. Charging amps measured 1.64 A = 30.34 Watt which is less than the original rated 33 W.

Time 01:30 - the PV panel has been steadily charging away with the voltmeters now showing the peak voltage at 13.87 V DC and 13.17 V DC at the lowest before returning to the peak. This indicates that the battery is showing more resistance as it loads which causes the peak voltage to drop.

Time 16:00 - after 3.75 hours of charging, peak voltage was 13.8 V DC and 13.17 V DC at the lowest.

Although there is still sunlight for more than 2 hours, a tree’s shadows will soon cover the PV panel so it is disconnected and the components stored away for another test the next morning.

Interestingly, the 12 V lead acid battery that had a nominal voltage of 12.65 V DC at the beginning of the test now reads 13.31 V DC which indicates that it has received some charge. Checking the battery voltage again at 21:30 gave a voltage of 12.85 V DC which is to be expected.

Is such a small amount of power of any practical use?

The possibilities will be the subject of a follow up in the next issue.

R. J. Godwin: Environment & Project Research

Some general Information:

What are Photovoltaics (PV)?

Photovoltaics (PV) is the conversion of light into electricity using semiconducting materials that exhibit the Photovoltaic effect, a phenomenon studied in physics, photochemistry, and electrochemistry.

A Photovoltaic system employs solar modules (PV Panels), each comprising a number of solar cells and are the best known method for generating electric power by using these cells to convert energy from the sun into a flow of electrons by the Photovoltaic effect. PV installations may be mounted on the ground, rooftop, wall or floating and may be fixed or use a solar tracker to follow the sun as it tracks across the sky.

Solar Photovoltaic power generation has long been seen as a clean energy technology which draws upon the planet’s most plentiful and widely distributed renewable energy source – the sun. Cells require protection from the environment and are usually packaged tightly in solar modules.

Additionally Solar PV has specific advantages as an energy source: once installed, its operation generates no pollution and no greenhouse gas emissions, it shows simple scalability in respect of power needs and silicon is plenty full in the Earth’s crust.

The first practical application of Photovoltaics was to power orbiting satellites and other spacecraft, but today the majority of Photovoltaic modules are used for grid-connected systems for power generation. In this case an inverter is required to convert the DC to AC. There is still a smaller market for stand alone systems for remote dwellings, boats, recreational vehicles, electric cars, roadside emergency telephones, remote sensing, and cathodic protection of pipelines. Photovoltaic modules were first mass-produced in Germany in 2000, for a ten thousand roof program.

Advances in technology and increased manufacturing scale reduced the cost, increased reliability and efficiency of Photovoltaic installations. More than 100 countries now use solar PV.

Actual power output at a particular location may be less than or greater than this rated value, depending on geographical location, time of day, weather conditions, and other factors. Solar Photovoltaic array capacity factors are typically under 25%, which is lower than many other industrial sources of electricity. After hydro and wind powers, PV is the third renewable energy source in terms of global capacity. At the end of 2016, worldwide installed PV capacity increased to more than 300 gigawatts (GW), covering approximately two percent of global electricity demand.

Advantages:

The 122 PW - 1 x PW (petawatt) = 1000 TW (terawatt) of sunlight reaching the Earth's surface is plentiful—almost 10,000 times more than the 13 TW equivalent of average power consumed in 2005 by humans. This abundance leads to the suggestion that it will not be long before solar energy will become the world's primary energy source. Additionally, solar electric generation has the highest power density among renewable energies.

Solar power is pollution-free during use, enabling it to cut down on pollution when substituted for other energy sources. Production end-wastes and emissions are manageable using existing pollution controls. End-of-use recycling technologies are under development and policies are being produced that encourage recycling from producers.

PV installations could ideally operate for 100 years or even more with little maintenance or intervention after their initial set-up, so after the initial capital cost of building any solar power plant, operating costs are extremely low compared to existing power technologies. Grid-connected solar electricity can be used locally thus reducing transmission/distribution losses.

Compared to fossil and nuclear energy sources, very little research money has been invested in the development of solar cells, so there is considerable room for improvement. Nevertheless, experimental high efficiency solar cells already have efficiencies of over 40% in case of concentrating Photovoltaic cells and efficiencies are rapidly rising while mass-production costs are rapidly falling.

Manufacturing:

The manufacturing process of creating solar photovoltaics is simple in that it does not require the culmination of many complex or moving parts. Because of the solid state nature of PV systems they often have relatively long lifetimes, anywhere from 10 to 30 years. To increase electrical output of a PV system, the manufacturer must simply add more Photovoltaic components. Economies of scale are important for manufacturers as costs decrease with increasing output.

While there are many types of PV systems known to be effective, crystalline silicon PV accounted for around 90% of the worldwide production of PV in 2013. Polysilicon is processed from mined quartz until it is very pure (semi-conductor grade). This is melted down when small amounts of boron, a group III element, are added to make a p-type semiconductor rich in electron holes. Typically using a seed crystal, an ingot of this solution is grown from the liquid polycrystalline. The ingot may also be cast in a mold. Wafers of this semiconductor material are cut with wire saws then surface etched before being cleaned. The wafers are then placed into a phosphorus vapour deposition furnace which lays a very thin layer of phosphorus, a group V element, which creates an n-type semiconducting surface. To reduce energy losses, an anti-reflective coating is added to the surface, along with electrical contacts. After finishing the cells are connected according to the specific application.

Crystalline silicon photovoltaics are only one type of PV, and while they represent the majority of solar cells produced currently there are many new and promising technologies that have the potential to be scaled up to meet future energy needs. As of 2018, crystalline silicon cell technology serves as the basis for several PV module types, including monocrystalline, multicrystalline, mono PERC, and bifacial.

Another newer technology, thin-film PV, is manufactured by depositing semiconducting layers on a substrate in vacuum. These semiconducting layers are made of many types of materials including cadmium telluride (CdTe), copper indium diselenide (CIS), copper indium gallium diselenide (CIGS), and amorphous silicon (a-Si). Thin-film photovoltaics now make up around 20% of the overall production of PV.

Other emerging PV technologies include organic, dye-sensitized, quantum-dot, and Perovskite photovoltaics. OPVs fall into the thin-film category of manufacturing, and typically operate around the 12% efficiency range which is lower than the 12–21% typically seen by silicon based PVs. Credit: https://en.wikipedia.org/wiki/Photovoltaics